|

| April 14, 2020 | Volume 16 Issue 14 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineering student builds ventilator prototype over weekend using Walmart parts

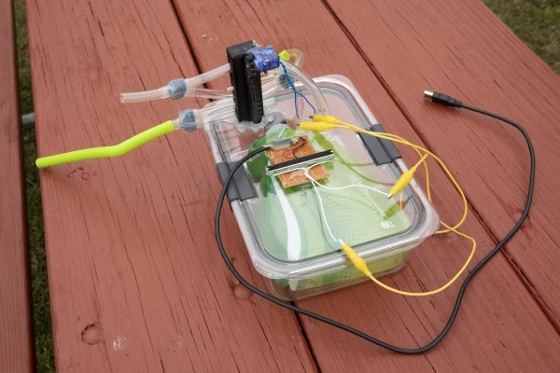

Jacob Goodman, a junior studying mechanical engineering at Binghamton University, State University of New York, made a ventilator at his campus residence mainly using items he bought at Walmart. [Photo: Binghamton University, State University of New York]

To help during the COVID-19 pandemic, a mechanical engineering student at Binghamton University, State University of New York, made a ventilator mainly over a weekend using items he bought at Walmart.

Over the years, Binghamton University mechanical engineering student Jacob Goodman has assembled potato guns, rail guns, a carbon dioxide laser, and "every type of rocket you can probably imagine." He's modified Nerf Guns to make them more powerful and improved the performance of every remote-control car and helicopter he's ever had.

So when a professor concerned about the spreading COVID-19 pandemic challenged him on a recent Friday (March 27) to build a working ventilator over the weekend, Goodman knew he could make it happen. By Monday (March 30), he did indeed have a prototype, which he put together in his residence hall room, mainly from repurposed parts he bought at Walmart.

Goodman, a junior from New Rochelle studying mechanical engineering at the Thomas J. Watson School of Engineering and Applied Science, found some inspiration from an Oxford University and King's College London project called OxVent, which uses a simple bladder inside of an airtight box to pump air into a patient's lungs.

"I probably spent more time walking around at Walmart trying to find supplies," he said. "A lot of this stuff is repurposed. The box is a lunchbox -- it's not perfectly airtight, but it does the job. The ‘bag' inside is a collapsing water bottle meant for camping. The connector that would go to the lungs is a silicone straw."

The ingenious part of the design, however, is a gear system that modulates the patient's breathing pattern. Goodman designed and printed it using his own 3D printer. The ventilator also includes some electrical odds and ends he had, and he owns an air compressor that he used to test it along the way.

"I think the best way to learn is to build something," he said. "I've taken that to heart. In high school, instead of sitting there and doing my homework, I would go and build things."

Although Goodman repurposed many items he bought at Walmart to create his ventilator, it also includes an innovative gear design to modulate a patient's breathing. [Photo: Binghamton University, State University of New York]

Goodman is one of Binghamton's Innovation Scholars, a three-year interdisciplinary program of academics, experiential learning, networking, and mentorship started in 2018 by School of Management Dean Upinder Dhillon and Vice Provost for Online and Innovative Education James Pitarresi. Each year, it brings together at least 25 sophomores from across campus to introduce concepts of design thinking, human-centered design, and "disruptive" idea generation that can drive economic development while also improving our everyday lives.

"We give them a toolset for creative thinking to solve wicked-hard problems," Pitarresi said.

He meets with the scholars once a week, but like all other classes at Binghamton, those seminars have moved online via Zoom.

"When we met virtually, we talked about how complicated ventilators are now, but it seems to me that 50 or 60 years ago they weren't that complicated," Pitarresi said. "We should probably be able to build one and then get some local companies to help us manufacture some. I like putting bold ideas out there.

"Jacob said, 'I think I could build one of these over the weekend in my room,' And I said, 'OK, I'm calling you out on this. I'm calling your bluff. There's no way you can do this.'"

Goodman's determination should not be underestimated, though.

"There are certain projects that I had to get done," he said, "no matter what was in my way, whether it was school or time or money -- I'd find a way to finish it."

jacob-goodman from Newswise on Vimeo.

VIDEO: Jacob Goodman, a mechanical engineering student at Binghamton University, State University of New York, built a ventilator prototype using mainly parts he purchased from Walmart to help during the coronavirus pandemic. Here he breaks down the parts and how the device works.

Assistant Professor Scott Schiffres and PhD candidate/lecturer Arad Azizi from Watson's Department of Mechanical Engineering praised the project's originality and suggested it might be worthy of a patent. Goodman is postponing pursuit of a patent for now, however, as he is eager to make his ideas available online as COVID-19 continues to spread and ventilator shortages persist.

"I'll put it out online and get as much feedback as I can," Goodman said. "I want to make this work and save some lives. If I lose my chance to patent it now, I've come up with a lot of good ideas. This isn't the first one, and it sure won't be the last."

Source: Binghamton University, State University of New York

Published April 2020

Rate this article

View our terms of use and privacy policy